Digital Print

UV digital printing is one of the most popular printing techniques used today. UV digital printing enables us to print a white base under any design and, results in vibrant colours even on dark surfaces. With accurate alignment and instant drying, UV digital printing is ideal for quick delivery and both short or long runs.

Artwork Requirements

- Use vector-based artwork.

- Illustrator compatible EPS or PDF with all fonts outlined.

- Indicate any critical colour elements with the correct PMS colour.

Branding Notes

- Quick turnaround.

- Vibrant design finishes on light and dark surfaces.

- Ideally suited for flat surfaces.

Moulded

Moulded in PVC, this specialised process transforms a brand or product design from an idea to the ultimate working 2 or 3D product. Suitable for use when supplying wireless chargers, flash drives, speakers, power banks, hubs and cables.

Artwork Requirements

- Use vector-based artwork.

- Illustrator compatible EPS or PDF with all fonts outlined.

- Designs can be supplied based on high-resolution images of all moulded aspects.

- Indicate any critical colour elements with the correct PMS colour.

Branding Notes

- Fully customised mouldings.

- 2D and 3D options are avalaible.

- PMS colour matched.

Pad Print

Pad printing involves the transferring of ink from a silicone pad onto the product. These pads come in all shapes and sizes, and whether an objects’ surface is flat like a power bank, or curved like a round speaker, these pads conform to the product shape and print the design accurately.

Artwork Requirements

- Use vector-based artwork.

- Illustrator compatible EPS or PDF with all fonts outlined.

- Indicate any critical colour elements with the correct PMS colour.

Branding Notes

- High-quality printing.

- Ideal when printing on uneven or curved surfaces.

- PMS colours can be affected by dark coloured product surfaces and may not be as vibrant as expected.

Laser Engrave

Laser engraving is used extensively in the promotional products sector when branding metal and eco-friendly products. In this process, the laser engraves into the exterior of a product. It removes the top surface of the product, revealing the required design and leaving the raw lower material exposed or burnt.

Artwork Requirements

- Use vector-based artwork.

- Illustrator compatible EPS or PDF with all fonts outlined.

Branding Notes

- Durable and permanent finish.

- Engraved surface finishes will vary depending on the base material with many surfaces showing a brass or copper finish.

- Aluminium oxides and turns white.

- Bamboo and maple will provide a burnt finished look.

- Ideal for branding on metal, however not recommended when engraving fine details onto Bamboo.

Light-up Logo

The light-up logo is created by engraving the top surface of the product to reveal the logo design, which is highlighted by the internal LED’s when the product is in use. With larger branding areas, the light-up logo effect can be further enhanced by using different coloured LED’s or by colouring the internal diffuser.

Artwork Requirements

- Use vector-based artwork.

- Illustrator compatible EPS or PDF with all fonts outlined.

Branding Notes

- Durable and permanent finish.

- High impact branding.

- Branding must remain within the stated area for maximum impact, due to LED dimming on the edges.

Epoxy Dome

Epoxy Dome stickers result from a process are where the design is directly digitally printed onto the stock and then coated with a protective layer of polyurethane. This transparent and glossy UV coating provides the ultimate protection against scratches in all types of weather conditions while enhancing and magnifying your brand for life.

Artwork Requirements

- Illustrator compatible EPS or PDF with all fonts outlined.

- Indicate any critical colour elements with the correct PMS colour.

Branding Notes

- Vibrant finish.

- 4CP digital design.

- Long-term branding option.

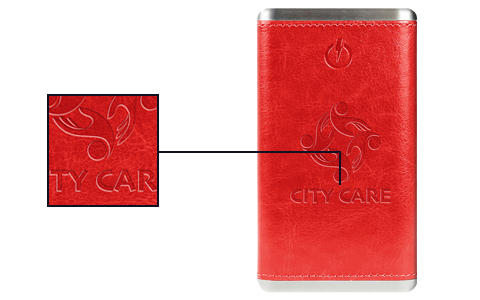

Debossed

Debossing is a method of stamping or indenting a design down into the paper, card, or leather stock to create a 3D effect. Debossing is the opposite of embossing and

Artwork Requirements

- Use vector-based artwork.

- Illustrator compatible EPS or PDF with all fonts outlined.

Branding Notes

- Ideal for branding on genuine or PU leather.

- Not recommenced when a design contains very fine detail.

Offset Print

Offset printing is the most common method when producing large volumes of printed material. In broad terms, offset printing works by transferring ink from metal plates to a series of rotating rubber sheets that in turn place the ink onto the paper stock. This method of printing produces sharp, high-quality print images and critical colour matching over long print-runs.

Artwork Requirements

- Use vector-based artwork.

- Illustrator compatible EPS or PDF with all fonts outlined.

- Indicate any critical colour elements with the correct PMS colour.

- Bleed is crucial, and the artwork must extend beyond the size dimensions for trimming and finishing purposes.

Branding Notes

- Consistent, high-quality images.

- Excellent colour matching.

- Ideally suited for long print-runs.

Sublimation

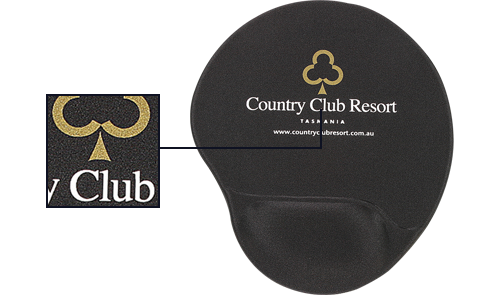

Sublimation is the process of printing a design onto transfer paper, which is then permanently dyed onto the fabric surface by applying heat and pressure. Sublimation printing is ideally suited for mouse pads, gel pads and cleaning cloths.

Artwork Requirements

- Image resolution should always be supplied at 300 dpi.

- Serif fonts such as Times should be 18 points or higher and sans serif fonts like Helvetica should be set to 12 points or higher.

- All reversed lines should be 1.5 pts, or higher and borders should not be used.

- Use vector-based artwork.

- Illustrator compatible EPS or PDF with all fonts outlined.

- Indicate any critical colour elements with the correct PMS colours

Branding Notes

- Ideal when printing multicolour designs or photos.

- The fine text will result in low legibility.

- Colours variations will occur during production.

Plastisol Transfer

Plastisol transfer is a specialised process where the design is printed directly onto special paper before being transferred under heat and pressure to the fabric surface. Ideally suited to finished products like gel pads, carry cases, and EVA cases.

Artwork Requirements

- Use vector based artwork.

- Illustrator compatible EPS or PDF with all fonts outlined.

- All critical colour elements must be assigned with the correct PMS colours.

Branding Notes

- Ideal 1 or 2 colour branding

- Provides a vibrant impact.

- Can PMS colour match.